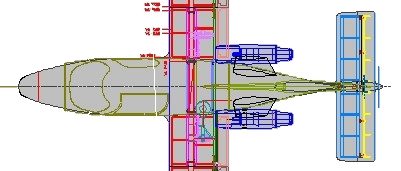

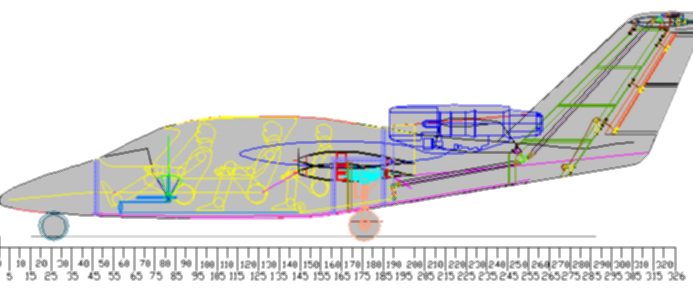

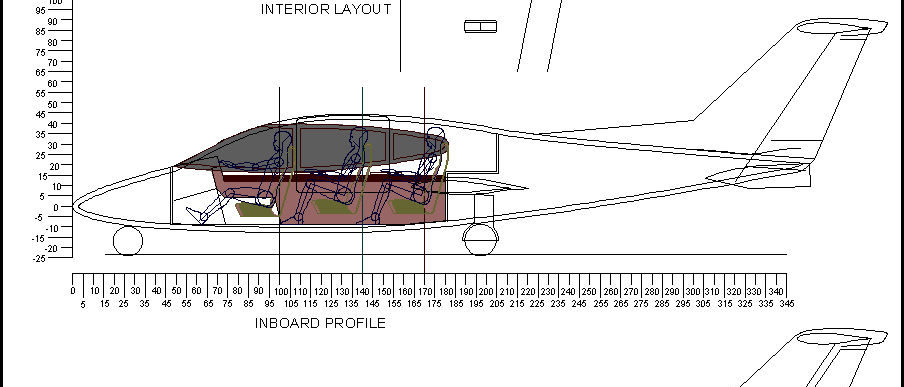

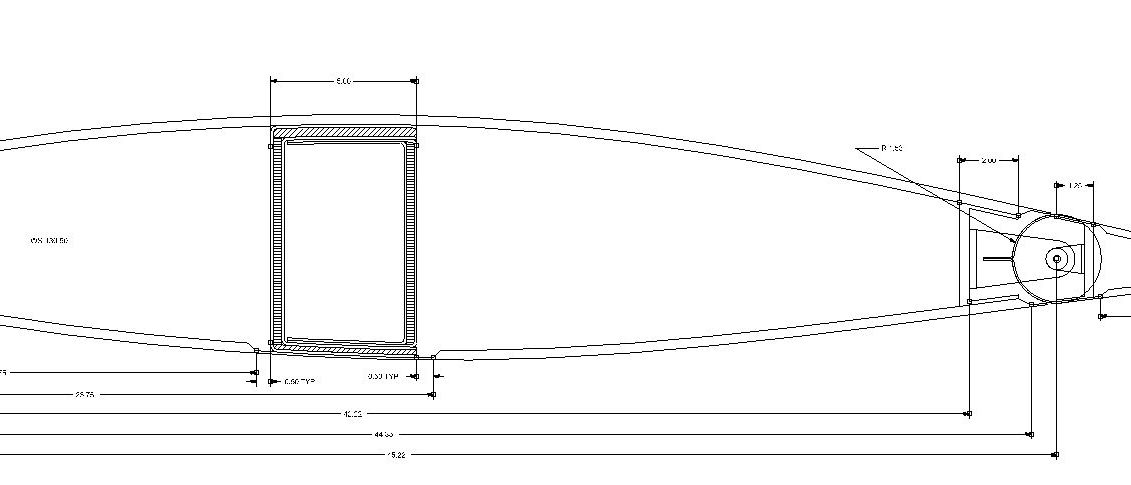

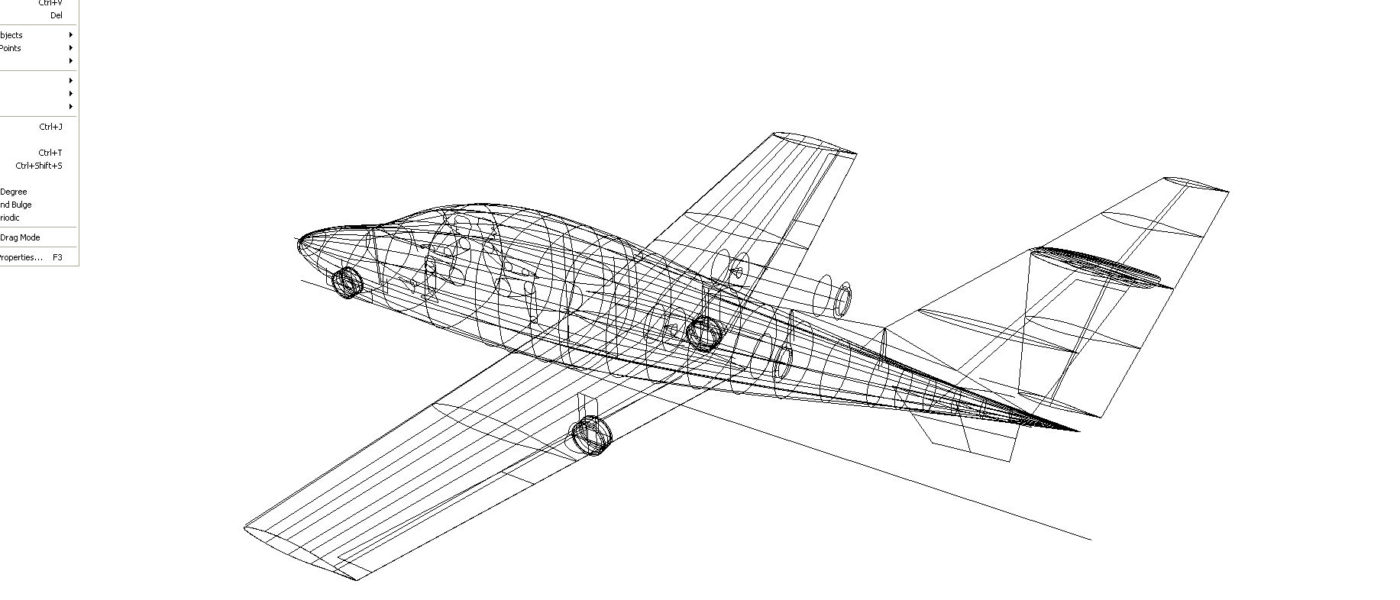

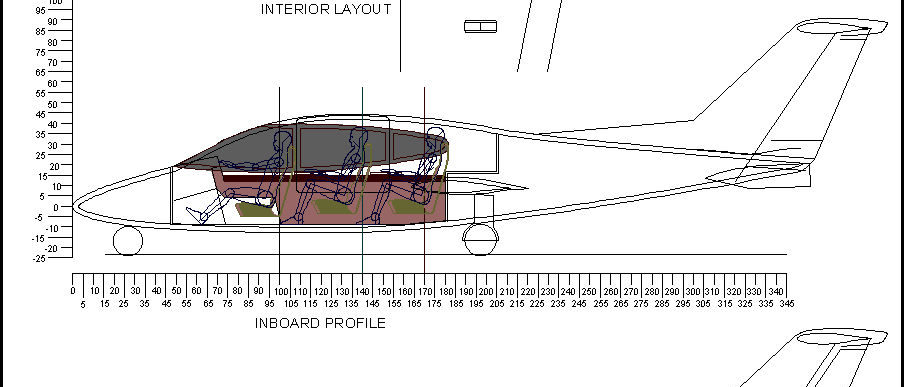

Under McCotter Aviation contract, Rob Schofield set up, managed the design and early production facility for the Maverick TwinJet, a 5 seat pressurized all-composite twin turbojet kitplane ($750K kit!), at Melbourne, Florida. 6 kits were built and flown. He moved the prototype and tooling from Penrose, Colorado, and Scapoose, Oregon and establishing a 42-employee composite production shop at the Melbourne International Airport.

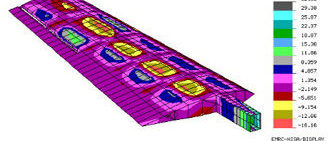

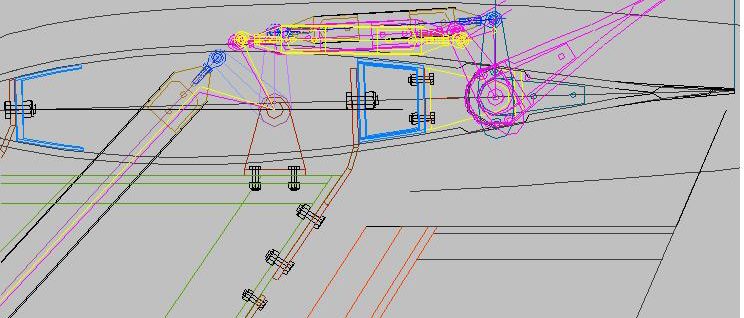

Rob was responsible for all engineering and performed structural design and flight testing of structures for all-composite 5-place, pressurized 31,000 ft capable, 400 knot kit airplane. Rob set up the initial production plant at Melbourne, FL. 2 aircraft flying as of present, 12 kits sold. Project was divided and moved to Poland for certification and for kit production in the former Soviet Georgia. Schofield joined the project in August 2000 as Vice President of Engineering and set up production, but left the company in July of 2002 to resume full-time his own engineering consulting business.

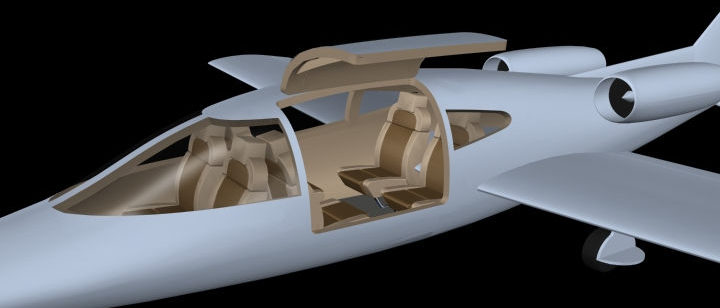

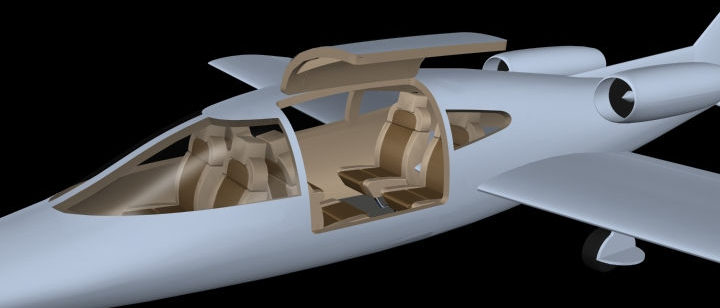

He designed a new 6 seat evolution of this airplane that used the Williams FJ-44 fanjet and put together a production-version design that was offered for certification through the Polish Aviation Institute and GILC (Polish FAA).

Rob has also designed several small 1 and 2 seat composite kitplanes from scratch, including his own SPITFAR and a 2/3 scale P-40, and engineered an all-composite wing replacement for the Titan Tornado kitplane.

Enstrom Helicopters TH-28: Schofield engineered and assisted in prototype fabrication of advanced lightweight composite fuselage, firewall, and cabin structures for the proposed TH-28 Army Trainer. A net 31% weight saving from the baseline design was realized for these components. The F-28 commercial model’s previous fiberglass laminate doors were flexing in flight and leaking rainwater. Schofield developed new laminates and structural configuration and

supervised fabrication of alternative design carbon fiber/vinyl ester and Kevlar doors which met the stiffness and weight requirements for that model.

Hover Systems Inc. HUSKY 400 Model Police, Search & Rescue Hovercraft:

Schofield performed structural design, arrangements, weight estimate, construction drawings, and consulted during fabrication of the prototype by Hovermarine, Ltd., Southampton, England. This lightweight, but rugged craft proved to be very inexpensive to build, achieved 35 knots in trials, and was found to be within 2 lbs. of his original weight estimate. Licensing arrangements are presently being made to manufacture the model in the U.S.